Our product lies in two categories:

(Product code list)

1-Bricks (Building and Face)

2-Tiles (Floor and Roof)

-

-

Bricks

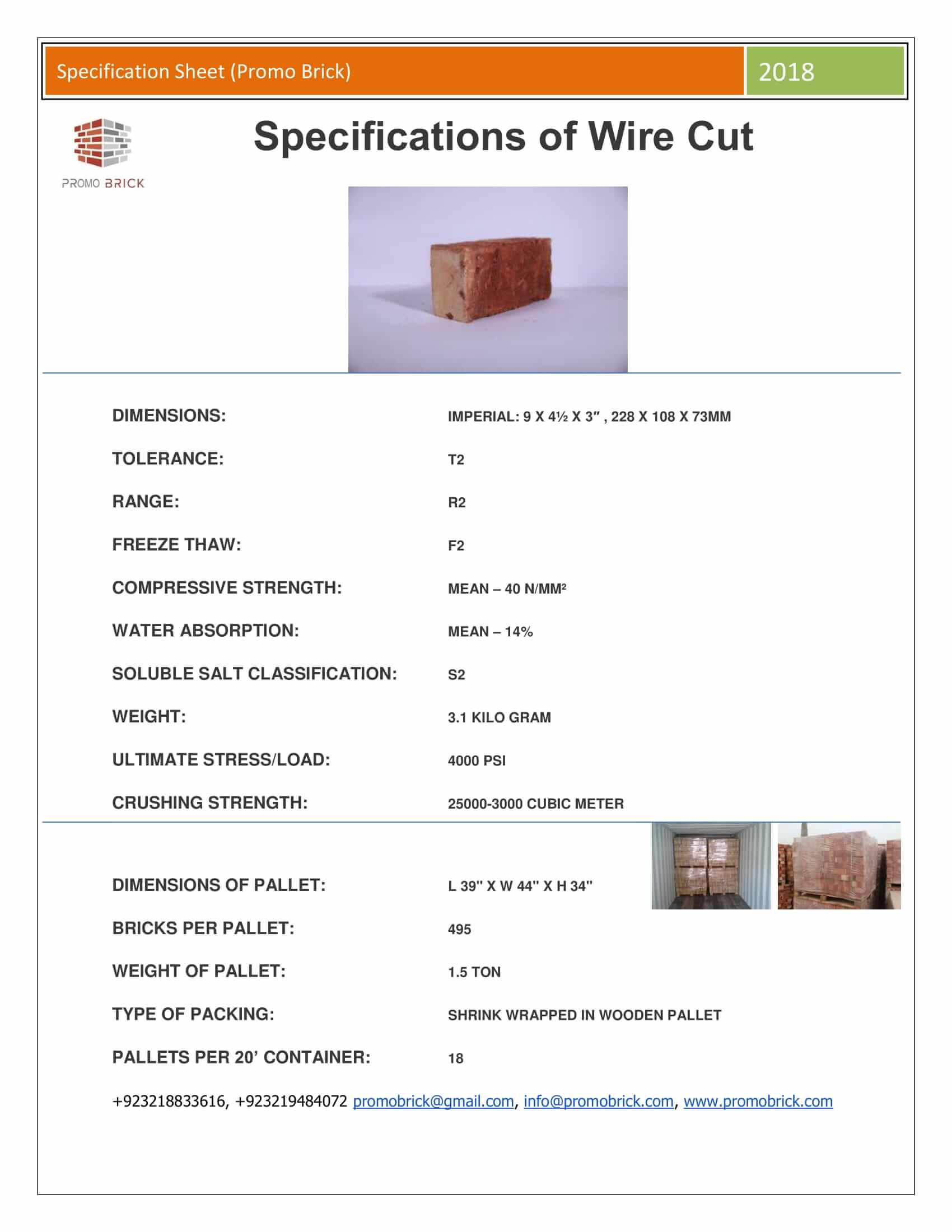

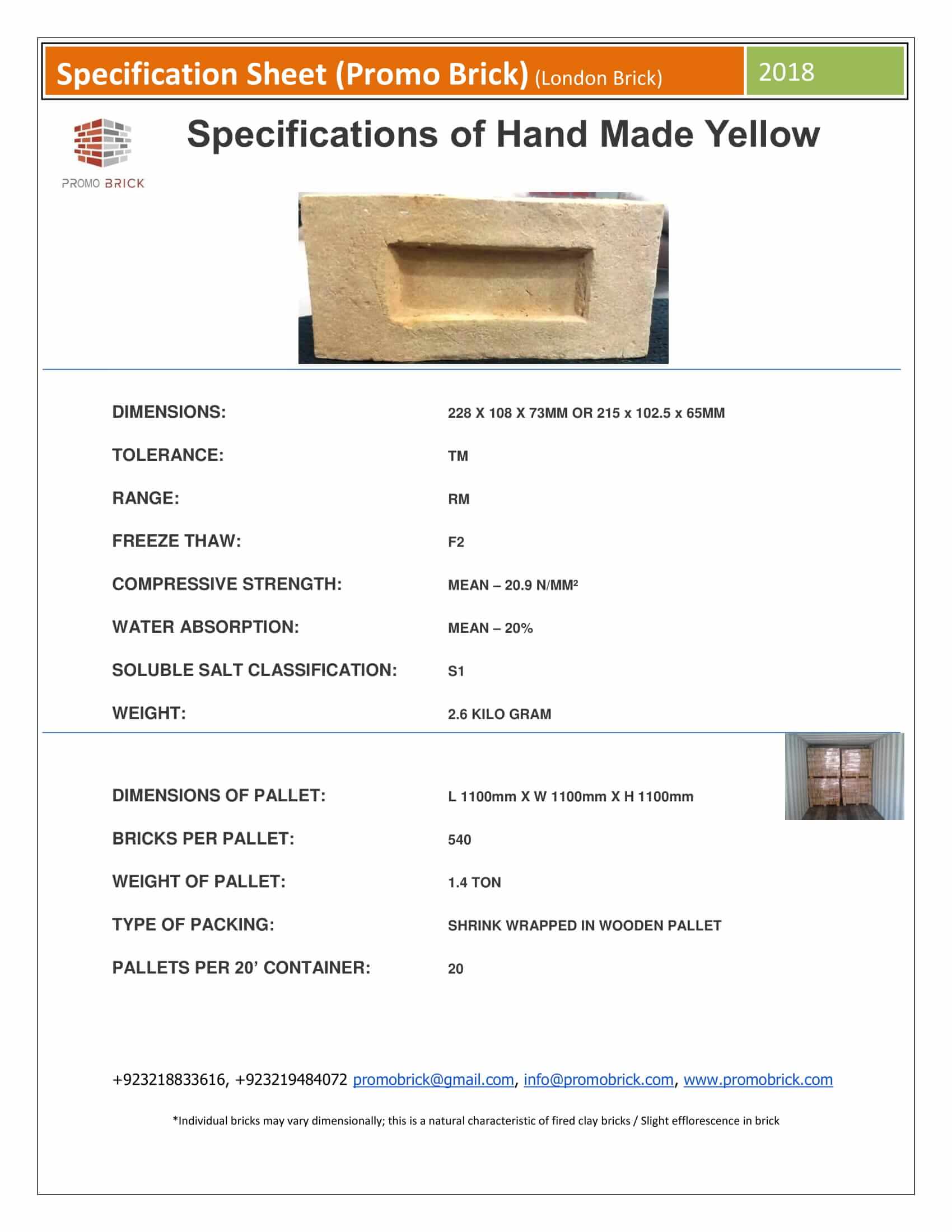

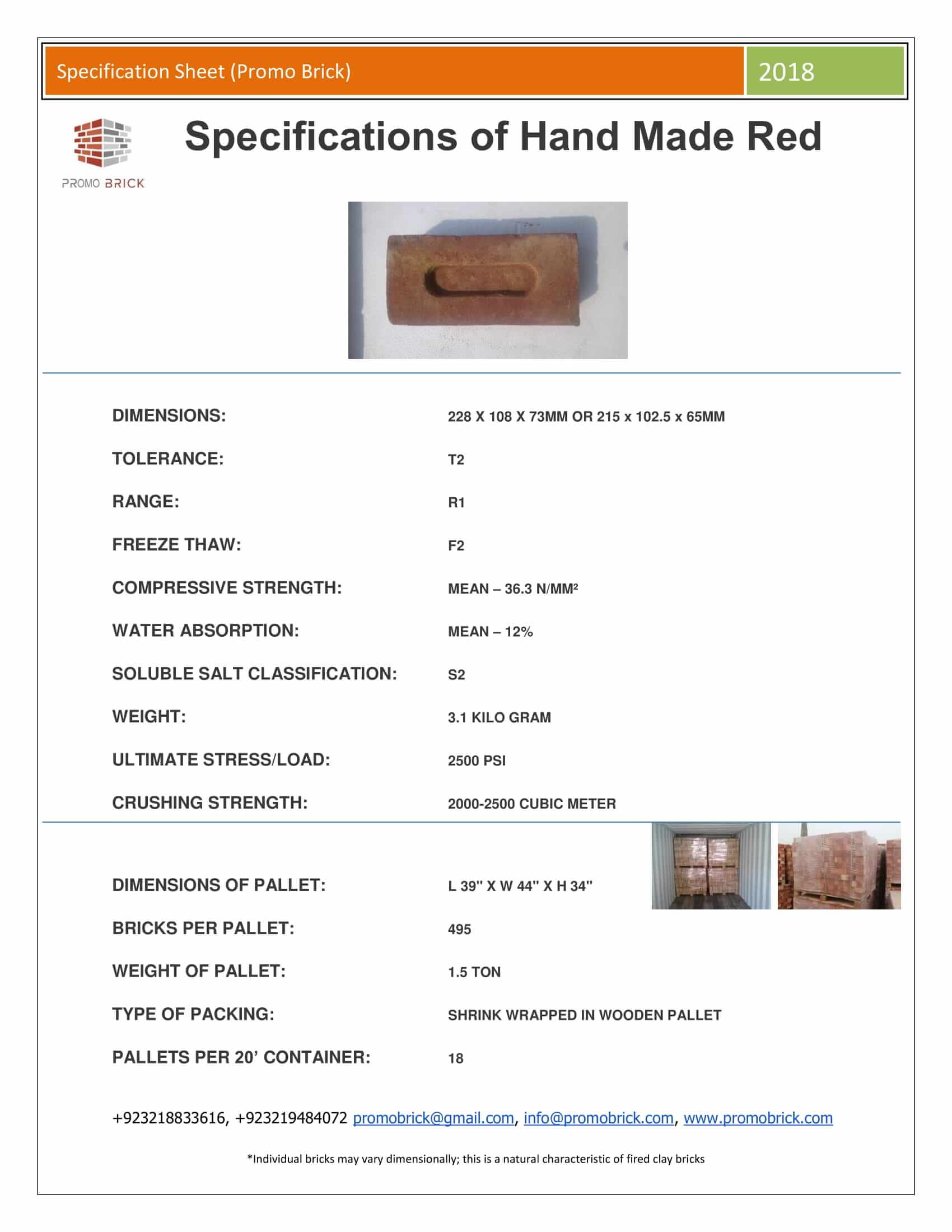

- Building Bricks

- Hand Made (BBHM-011)

- Wire Cut (BBWC-012)

- Machine Press (BBMP-013)

-

Face Bricks

- Standard Size (FBSS-021)

- Customized Size (FBCS-022)

-

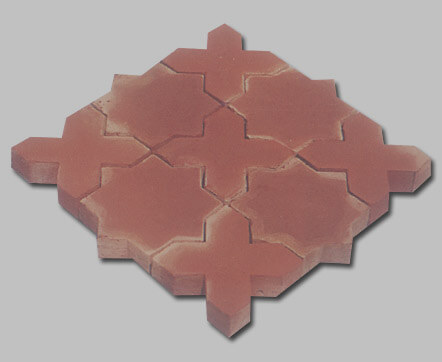

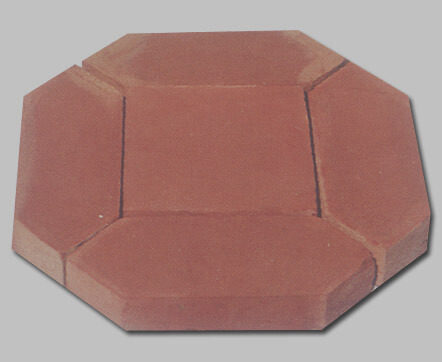

Designs

- Patterns (FBPD-023)

- Border (FBBD-024)

- Top Edge (FBTE-025)

- Pillar (FBPD-026)

-

-

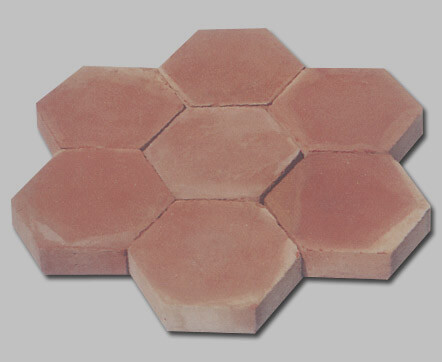

Tiles:

- Floor tiles (TBFT-031)

- Roof tiles (TBRT-032)

Note: If there is more than one design for a category like Patterns, put -1, -2 till the end for the codes.